The cover rubber is especially compounded for the applications requiring resistance to oils. It has outstanding abrasion, ozone and weather resistance. This conveyor belt is recommended for the conveyor lines causing swelling and sponginess by oils.

Special Features

- >OR-300 grade has excellent resistance to the toughest oil application such as oil-treated coal, petroleum based oils.

- >OR-200 is grade has superior oil resistance to various kinds of animal and vegetable oil with severe cold temperature up to - 45°C (50°F).

- >OR-100 grade is to resist to Moderate Oil Resistant operations like wood chips, linseed, cottonseed and whole soybeans where static conductivity is needed.

- >HTN grade is recommended for conveying hot asphalt with temperature up to 175°C (350°F) where both oil & heat resistance are required.

Cover Rubber Grade

| Type | Cover Rubber | Use | |||

|---|---|---|---|---|---|

| Min. Tensile Strength | Min. Elongation % |

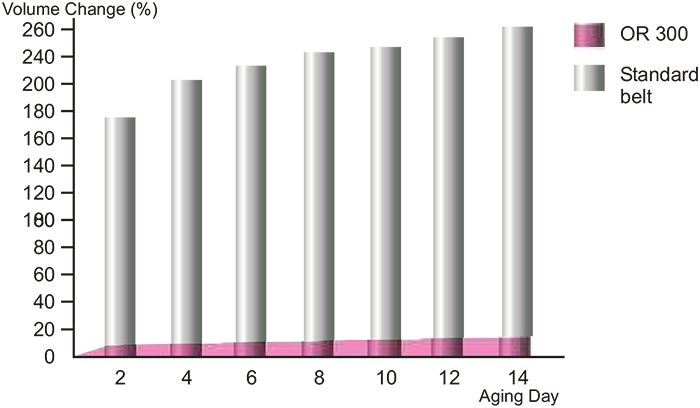

Volume Change ASTM # 3 Oil |

|||

| kg/cm2 | psi | ||||

| OR-300 | 160 | 2250 | Min 500 | Max 20 | Oily metal parts, crushed soybeans, automatic hydrocarbons such as benzol, toluene and petroleum based oils. |

| OR-200 | 120 | 1700 | Min 500 | Max 90 | Oil-treated materials and for carrying oily metal turnings and shavings, crushed soybeans, animal or vegetables fats. |

| OR-100 | 140 | 2000 | Min 450 | Max 150 | Wood chip, linseed, cottonseed, kernel corn, and whole soybeans, static conductivity and moderate oil resistance. |

| HTN | 120 | 1700 | Min 500 | Max 60 | Hot asphalt, coke whafs, and other oil & heat resistant applications. |

OR-300 Resistant

-

Excellent (Oil Resistant Belt) Moving

-

Swelled by Oil (Standard Belt) Moving